Automation of packaging and storage processes in the food industry requires the highest standards of hygiene and durability. We offer stainless steel palletizing systemsthat meet strict sanitary and hygienic standards and ensure reliable operation even in demanding production conditions.

Automation of packaging and storage processes in the food industry requires the highest standards of hygiene and durability. We offer stainless steel palletizing systemsthat meet strict sanitary and hygienic standards and ensure reliable operation even in demanding production conditions.

Advantages of stainless steel palletizing:

✅ Resistance to corrosion and chemicals – ideal for contact with food and for working in damp environments.

✅ Easy cleaning Smooth surfaces and the absence of hard-to-reach areas minimize the risk of contamination.

✅ Durability and reliability – resistance to intensive use in production facilities.

✅ Compliance with HACCP and FDA standards - ensures safety and compliance with sanitary regulations. FDA

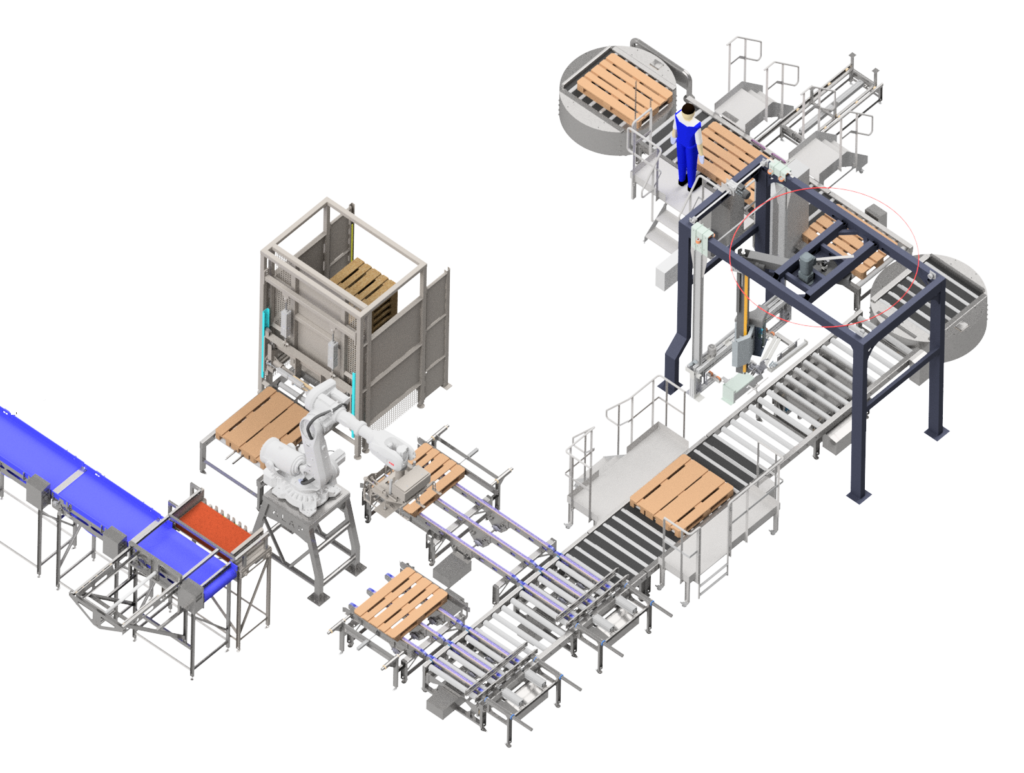

Our solutions include:

? Automatic stackers and de-stackers – precise and fast palletizing.

? Transport systems – roller and belt conveyors made of food-grade materials.

? Grippers and manipulators – suitable for fragile packaging such as bottles, cans or cardboard boxes.

? Modular palletizing systems – flexible solutions tailored to different product types.

Our palletizing systems make your food production more efficient, safer and compliant with standards. Find out how we can optimize your logistics process!

Benefits

Projects

See how our solutions are changing industries - check out our implementations!

Collaboration

Learn how we take projects step by step to achieve success together.

Inspiration and knowledge

Visit our blog and discover interesting articles that can inspire you.