Automatyczny podajnik palet to niezawodne rozwiązanie do transportu palet w magazynach, na liniach produkcyjnych i w centrach dystrybucyjnych. Dzięki zaawansowanej technologii system umożliwia szybki i bezpieczny transport palet, minimalizując ryzyko błędów i zwiększając efektywność procesów logistycznych.

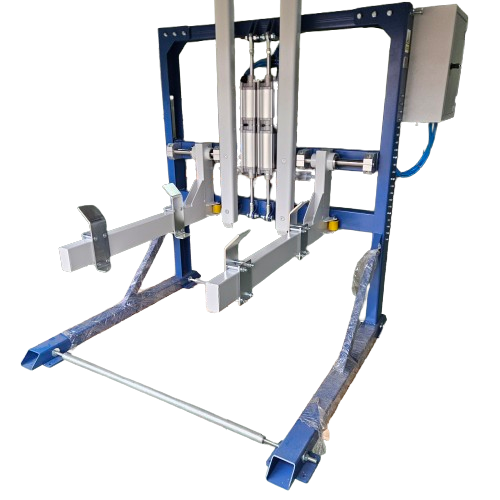

Automatic pallet dispenser is a modern device that significantly improves the efficiency of pallet transportation in various industrial environments. By using drive systems such as rollers, conveyor belts or chains, the feeder ensures the smooth movement of pallets of different sizes and weights, enabling fast and reliable loading and unloading.

Mechanizm działania – precyzja na każdym etapie

Automatyczny podajnik palet to rozwiązanie, które pracuje w dwóch trybach, zapewniając zarówno podawanie, jak i odbiór palet. W procesie podawania podajnik palet pobiera pojedyncze sztuki ze stosu, a następnie wprowadza je w sposób kontrolowany na linię transportową. W trybie odbioru podajnik do palet przyjmuje palety z linii i precyzyjnie odkłada je na stos. Taki mechanizm jest niezwykle ważny dla zachowania ciągłości pracy – eliminuje manualne operacje ze strony pracownika, co jest szczególnie istotne w przypadku podajnika pustych palet w procesach paletyzacji.

Podajnik do palet – właściwości techniczne i możliwości personalizacji

Our automatic pallet dispensers are the ideal solution for intensive warehouse and production processes where precision and efficiency are key. Thanks to the possibility of integration with warehouse management systems (WMS) and automated transport lines, these devices enable full automation of pallet loading, transportation and sorting processes. The feeders can also be adapted to specific requirements, such as handling different pallet sizes, variable transport speeds or different drive types.

Nasze podajniki palet na zamówienie są projektowane z myślą o maksymalnym dopasowaniu do specyficznych warunków produkcyjnych i logistycznych. W zależności od potrzeb automatyczne podajniki palet mogą być wyposażone w funkcje takie jak czujniki wykrywające obecność palet, mechanizmy spowalniające oraz funkcje bezpieczeństwa, które zapewniają ich niezawodność i zgodność z obowiązującymi normami.

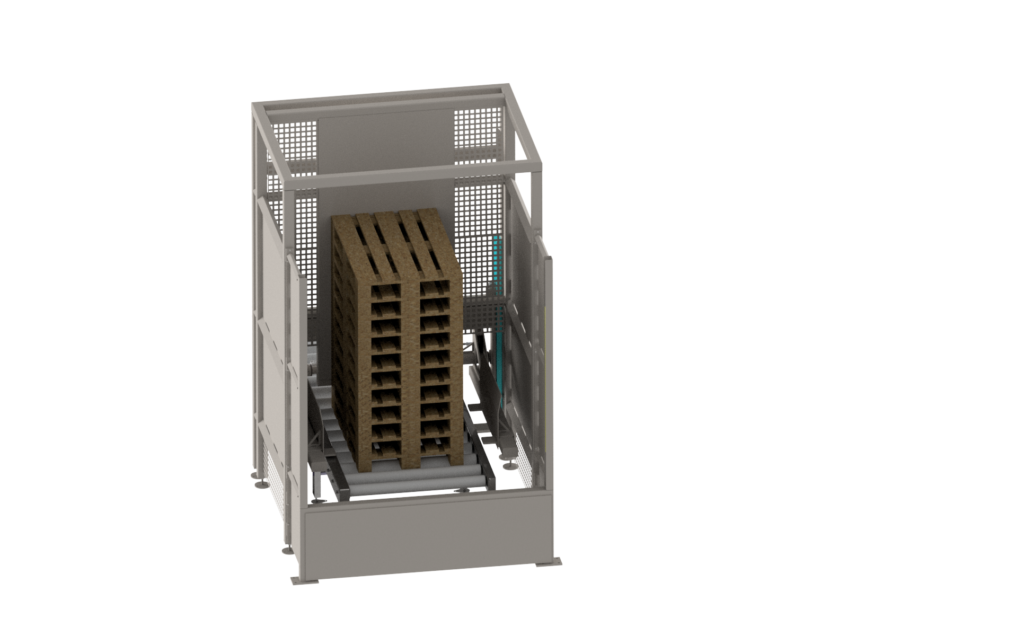

Automatic pallet warehouse to niezawodne i efektywne urządzenie przeznaczone do składowania oraz podawania palet w zautomatyzowanych liniach produkcyjnych i logistycznych.

Umożliwia precyzyjne zarządzanie ruchem palet, redukując czas obsługi i zwiększając bezpieczeństwo pracy.

Najważniejsze zalety podajników do palet

Nowoczesny, automatyczny podajnik palet to inwestycja, która przynosi wymierne korzyści. Jego wdrożenie pozwala na optymalizację całej linii produkcyjnej i znacząco podnosi jej efektywność. Każdy podajnik palet jest projektowany tak, aby zminimalizować przestoje i stworzyć środowisko pracy, w którym płynność i bezpieczeństwo są priorytetem.

Advantages and functions:

✅ Automatic pallet feed – eliminates the need for manual loading and unloading.

✅ Space optimization – the compact design allows for efficient use of storage space.

✅ Fast and smooth operation – the system allows for precise picking up and delivery of pallets to conveyors or palletizing robots.

✅ Reduction of operating costs – reduces the need for manual labor, increasing operational efficiency.

✅ Integration with automation systems – the ability to work with transport lines, palletizing robots, and ERP/WMS systems.

✅ Safe operation – equipped with sensors and safety systems to prevent collisions and malfunctions.

Thanks to the automatic pallet warehouse, it is possible to increase the efficiency of logistics processes and eliminate downtime due to a lack of pallets in the production line. The device is an ideal solution for companies that focus on automation and work optimization.

Benefits

Projects

See how our solutions are changing industries - check out our implementations!

Collaboration

Learn how we take projects step by step to achieve success together.

Inspiration and knowledge

Visit our blog and discover interesting articles that can inspire you.